Thermal Oxidiser – Dickinson Legg

Project Details

Customer Name: Dickinson Legg

The Brief: Provide heat for drying tobacco products and oxidise waste gas.

Location of Installation: China, Indonesia, Vietnam, South Korea, Turkey, Chile, Germany, Egypt

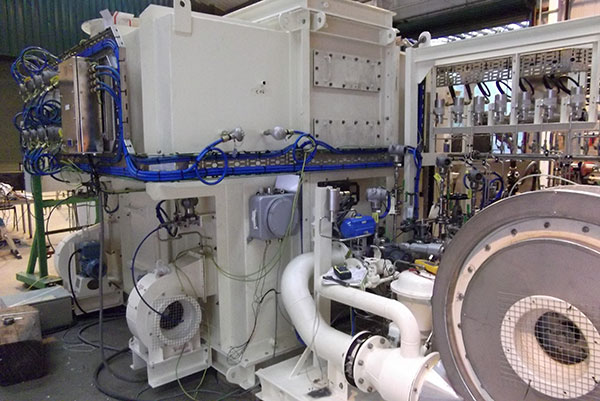

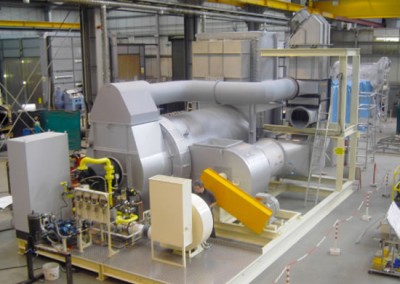

Products supplied: Thermal Oxidiser and integrated Process Heater

Project Duration: Typically 7 months

The Solution

Tobacco processing is a specialised and highly automated industry; Process Combustion has supplied over twenty Thermal Oxidiser systems for a variety of clients across the globe.

In these installations:

- The thermal oxidiser helps provide heat into the tobacco drying loop using a recycle heat exchanger. An exhaust stream from the drying loop is supplied to the thermal oxidiser where it reaches a temperature of 800° C to oxidise contaminants. Waste heat is also recovered to pre-heat the waste stream and combustion air.

- The equipment supplied by Process Combustion typically includes a thermal oxidiser chamber lined with ceramic fibre blocks, a dual fuel burner, fans, fuel gas and oil trains, a recycle gas heat exchanger and a waste gas pre-heater, duct-work, a skid base frame and a burner management system.

Related Case Studies