Thermal Oxidiser – Scottish Leather Group

Project Details

Customer Name: Scottish Leather Group

The Brief: Scottish Leather were sending 30, 000 tonnes of waste to landfill each year. Turn that waste into heat and steam for processing leather and heating water

Location of Installation: Bridge of Weir, Scotland

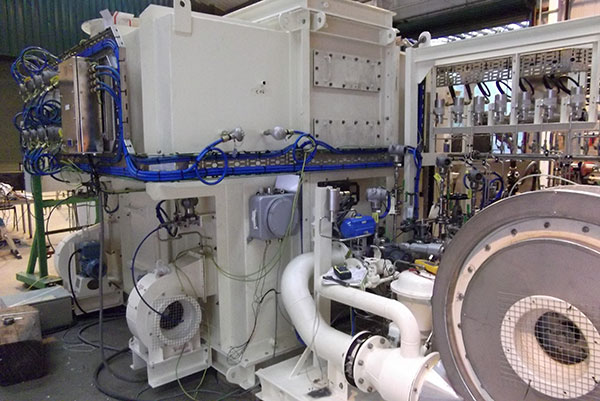

Products supplied: Thermal Oxidiser, Boiler and Gas Clean-Up System

Project Duration: 9 months

The Solution

A thermal oxidiser burns a syngas generated from the gasification process resulting in high temperature exhaust gas. A waste heat boiler was installed that recovers heat and generates the steam from the exhaust gas. The clean-up system also includes a ceramic filter plant and SCR.

- The plant is a world first in the industry and leads the way in low carbon leather manufacturing. Scottish Leather are high quality, specialist supplier to the automotive and aircraft industries

- Waste that would have gone to landfill at the rate of 100 tonnes per day is now generating thermal energy, helping reduce carbon emissions and saving Scottish Leather substantial landfill taxes.

Related Case Studies